Contents

The volma printed on packings of dry mix a layer, the instruction contains all data necessary for plastering performance. We will pay attention to nuances, the famous plasterers, but often unknown beginners. This lack of knowledge can wake in beginning plaster technological "amateur performance" which result is a rejected finishing. Means, time and forces, and walls are spent upset with network of cracks, the appearing spots, and even the disappearing plaster layers. Not to be disappointed in products of the Volma brand, comprehend nuances of plaster skill.

The tool for work

To plaster manually (not important at the same time what structure), classical and modern use tools.

So, will be necessary for preparation of mix:

- the mixer construction (if it is absent, it is possible to use for hashing the electric drill with a nozzle);

- trowel;

- the pallet (for removal from walls of capacity not of promeshenny mix).

To dissolve dry mix, take plastic capacities which have to be clean, dry. Volume depends on the speed of production of plaster solution (experience of plasterers, their quantity), for the beginner plastering alone, first will be a basin up to 60 l enough. Also the container with water is required (bucket) in which wash a mixer nozzle after use.

For preparatory work:

- pallets and other tool for removal of an old covering;

- the roller, brush (for priming);

- the pallet for repair of cracks, splitting off;

- level (for check of vertical position of a wall, installation of beacons), is better laser;

- cords and plumb (if there is no laser level).

Directly apply to plastering:

- trowel

- the rule (h-shaped for leveling, trapezoid for undercutting);

- spongy grater (the tool "zamochalivat" and polish);

- pallet (wide);

- gladilka.

Pallets, a gladilka have to have a working part from stainless steel.

For upclassing of a surface impressive/structural rollers and other devices can be used.

Also will be necessary:

- pencil (for a marking);

- painting adhesive tape;

- film (for protection of adjacent surfaces, frames and glasses);

- roulette;

- garbage bags;

- step-ladder or scaffolding;

- carrying for control (by means of angular light) qualities of a surface;

- clean rags.

We prepare walls

Purpose of this stage:

- ensuring strong coupling of a new covering with the basis;

- elimination of sources of a prostupaniye on finishing finishing of spots;

- protection of walls (basis) from appearance of biosettlers (a mold, a fungus);

- protection of a connecting layer against destruction, for example, from receipt and accumulation of water;

- protection of the tsementosoderzhashchy bases against influence of the sulfates emitted by the becoming wet plaster;

- decrease in a consumption of the leveling mixes;

- strengthening of a surface of the weak basis;

- protection of plaster solution against dehydration (on the porous bases).

All these objectives are achieved by performance of a complex of the operations applied to all room.

In case of repair of old walls delete paint, filled, panels of wall-paper, the lagged behind or just weak, crumbling plaster, eliminate dust.

Further for new and old walls of work are similar:

- examine walls, revealing defects, defects, geometrical parameters;

- clean the basis from fatty spots, traces of a soot, rust, decay;

- seams of a bricklaying deepen jointing, on concrete do notches;

- repair cracks, hollows, a big splitting off;

- delete metal elements (unnecessary nails, hooks) which remained isolate;

- joints omonolichivat solution, imposing a grid;

- ledges cut down;

- ground a surface (apply priming structures of deep penetration to closing of a time);

- mount beacons, reinforce (if necessary);

- after installation of beacons in addition ground the surface of solution of their attachment.

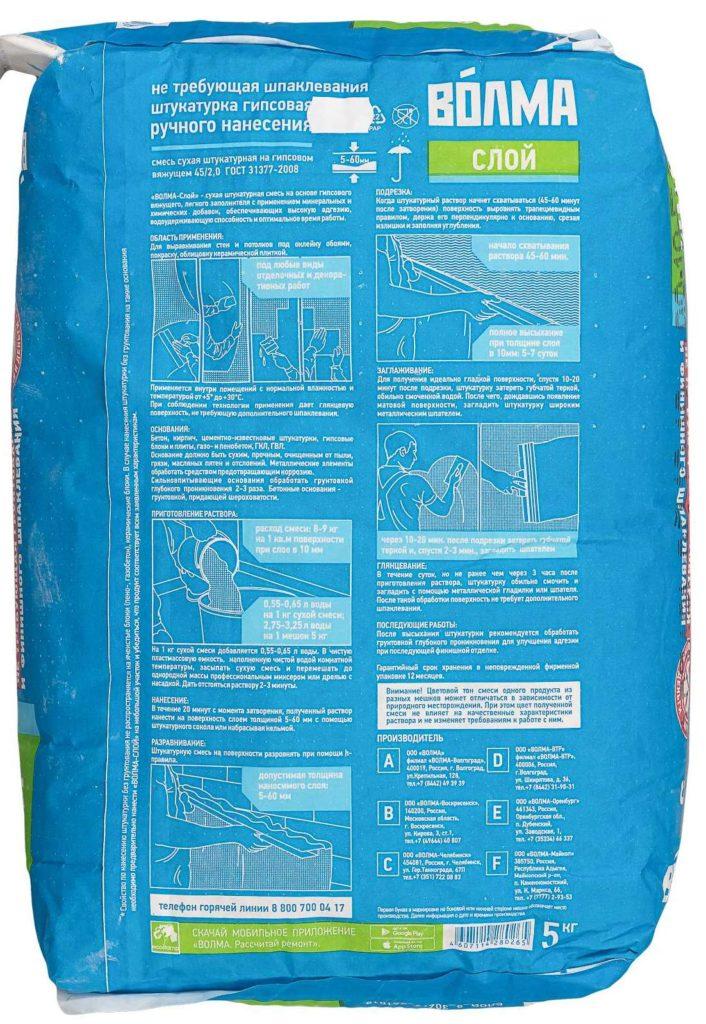

How to part a volm a layer

To part 30 kg of dry powder of a volm a layer, the instruction for application recommends to take 18-19 liters of tap cold water. The water consumption approximately is specified. Therefore it is necessary to bring consistence of solution to desirable during mixing.

It is connected with several factors, for example, for drawing weight a thick layer, the dense consistence is necessary. Therefore for a start in capacity pour not all specified volume, leaving for finishing 3-4 l separately (for emergency). If when mixing plaster plaster turns out dense, add liquid from a stock, adding portions.

At a zatvoreniye of smaller weight, the volume specified by the producer is reduced in proportion and also leave a portion for emergency. So for 10 kg of mix take 6-6.3 l. The volume of the water poured in capacity should not occupy more than a third of its volume, otherwise a part of solution will appear on a floor.

Water take by all means cold. Temperature increase of water for a zatvoreniye sharply increases the speed of course of all chemical reactions. Therefore the term of life of solution is reduced that is undesirable.

Mix water with powder the mixer on small turns. To the center the pallet or a trowel remove from capacity walls and throw back stuck nepromes. Once again mix, trying to obtain disappearance of lumps.

Feature of process of a zatvoreniye and hardening of plaster structure is its ability at hit of lumps of old solution to become "stake". In fresh solution at the normal course of process the centers of crystallization appear not at once, only at a certain stage.

But already such centers have lumps of earlier shut plaster therefore, in turn, having got to fresh solution (at any stage) become catalysts of formation of the new centers and serve as them.

After the first mixing to solution give 3-4 minutes to stand, again mix. After that weight can be applied on a wall.

How to plaster walls volmy

Manual putting plaster of a volm a layer is similar to putting any leveling plaster mix. At the same time plaster mix is so eco-friendly that it is possible, without being afraid of consequences, to form by a hand. Depending on a task and a condition of the basis three methods of drawing are possible: the pallet (at a plain surface) apply and level a thin film; under the rule – without beacons put weight where achievement of high-quality finishing is not required; on beacons level walls with big flaws.

Article about ways of alignment of walls can be also interesting to you.

Temperature of the basis and air should not be higher than +30, below +5os. The humidity – is not higher than 65%.

On beacons

To plaster a wall, use guide plates – the beacons forming the auxiliary vertical plane. Mayakovy profiles (metal, plastic, wooden or solution) have with a step of 1.0-1.3 m. As plaster of a volm – plaster, solution beacons from the same solution will be the best. They do not need to be deleted after plastering, the main thing, after production of solution guides to ground them before plastering.

Cover with dough slaps from below up between two next levels. Having filled the site about 1 sq.m, level solution the h-shaped rule, conducting it along guides. The excess weight which the pallet is returned on a wall there where it is less solution gathers on the tool. Having carried out by the rule 2-3 times, continue filling with solution of an interval between beacons, then pass to filling of the next path formed by profiles.

In 40 minutes from the beginning of a zatvoreniye the trapezoid rule put by an edge it is perpendicular to a wall, carry out undercutting. Move the rule in the same direction in what leveling – from below up was conducted. If undercutting of a message across the direction of smoothing, teases can be formed.

Precisely to define time of performance of the second undercutting, apply the test in which the hand is used, – the so-called test on "lindens". The touch by a hand to a surface leaves a solution mark on a palm – stuck. Start the second undercutting when "leaves" lindens, and the surface becomes opaque. When pressing by a finger on a surface traces still remain, but to a finger dough does not stick.

Undercutting is carried out the pallet, conducting him it is perpendicular to a wall. At this stage, "collected" from a surface, solution is required for filling of cavities. By the pallet it is not necessary to do the smoothing movements, disposing him at an acute angle to a wall. At this stage do only undercutting, not especially leaning on the tool.

The instruction to a volm a layer gives extreme sizes of thickness of the layer put for one pass. According to it, volmy layer up to 60 mm is applied. Such thickness is possible only on vertical surfaces, on small sites. And dough has to be dense that did not slip under a body weight down.

For ceiling overlappings the maximum thickness is reduced to 10 mm. Do it for safety (in case the products got delayed, water, etc. from above leaked). The minimum thickness – 3 mm. Rational values – 5-30 mm.

Without beacons

At this method of plastering the rule leans on the existing surface hillocks, and solution fills all deepenings on the way of the movement of the tool. Putting solution is carried out twice. After drying-out of the first layer, fill the remained dimples, a time, conducting the wide pallet across the movement of the rule at the first pass.

Zatirka and steeling

After undercutting wait for 10-30 minutes, then carry out a zatirka (still called by "zamochalivaniye"). The procedure purpose – to expel from a time a plaster milk and to putty them the smallest roughnesses. The wall (when the surface of the laid solution becomes opaque) is plentifully moistened by means of a gubochny grater with circular motions. The procedure does not demand strong pressing. Conducting on a surface the wide pallet, squeeze out a plaster milk from a wall. The milk (semi-fluid plaster weight) gathering on an edge putty the remained time.

Steeling (or glossing) is done if you want to receive the glossy surface suitable under paint. Choose time (no later than 24 hours since the beginning of a skhvatyvaniye, not earlier than 3 hours since the same time), moisten a surface, and then with effort by the pallet carry out on a wall, pressing small cambers.

Drying

Having jammed or having smoothed down the applied solution, the wall is left to dry. The wall has to dry in the natural way. On drying of a layer of 10 mm (according to the instruction) 5-7 days are required. In practice this time can differ. It depends on thickness of the laid solution, humidity and temperature indoors.

For what surface plaster of a volm a layer is suitable

Thanks to the small weight and also other properties, the volma finds application in alignment of the bases from various materials:

- concrete (monolithic and assembly);

- bricklaying;

- plaster blocks or plates, gypsum cardboard;

- cellular concrete, for example, foam, gas concrete;

- strong old plasters on a limy or cement and sand basis.

Pay attention: as the layer, the instruction for use of plaster, structure published on packing of a volm reports it is possible to impose on walls without preliminary priming. However it does not concern the silnoporisty bases, such as gas concretes and ceramic blocks. Takzheneobkhodimo primer use (the best structure – Akvastop) when plastering gypsum cardboard. It is done in order that during removal of a plaster layer the cardboard wrapper of hl was not damaged.

That who already has the experience of plastering, but the layer did not face application of a volm, the instruction will help to refresh the main inclusion in memories, will prompt volumes and conditions which should be observed.

(yet there are no estimates)

(yet there are no estimates)

What plaster for walls to choose – the rating of plaster, cement and limy mixes

What plaster for walls to choose – the rating of plaster, cement and limy mixes